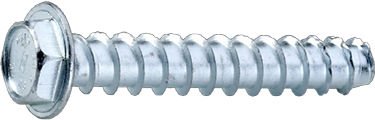

The most common types of machine screw head shapes are pan head, flat head, round head, oval head, truss head and hex head. While round heads are probably used most often, flat heads are particularly useful when the screw needs to be flush with the surface it’s screwed into The two main drive types associated with machine screws are slotted (flat head) and Phillips. There are also a number of specialized drives that they can come in, these are typically associated with tamper-resistant screws. Some of these drive types include, – six pointed, spanner, and trident to name a few.

Machine screws are used to put metal parts together. They come in a variety of head types and lengths. Machine screws are one of the “exceptions” to our rules in that while they normally thread themselves directly into a hole within the metal, they do, on occasion may be used with a nut.